Yes, that's right - adhesive printing in digital printing! The first attempts in this direction were a complete success. Why digital printing? And for which applications?

The future is contactless and revolutionary!

Why is adhesive printing in digital printing so revolutionary?

Normally, liquid adhesive is applied to the material to be printed, the substrate, using a squeegee in a screen printing process. In our test, we used a PET film as the substrate, to which the adhesive was applied using digital printing in a layer thickness of less than 50 µm.

Digital printing has clear advantages in the "adhesive printing" process

- Its non-contact printing process minimises the risk of damage to sensitive substrates

- Faster cycle and curing times thanks to UV light compared to other curing mechanisms (e.g. heat curing)

- The production process requires less space and significantly less energy

New possibilities in fuel cell production

Where exactly is non-contact digital printing needed?

In collaboration with DELO, our Technology Center has carried out initial tests to apply special adhesives using digital printing.

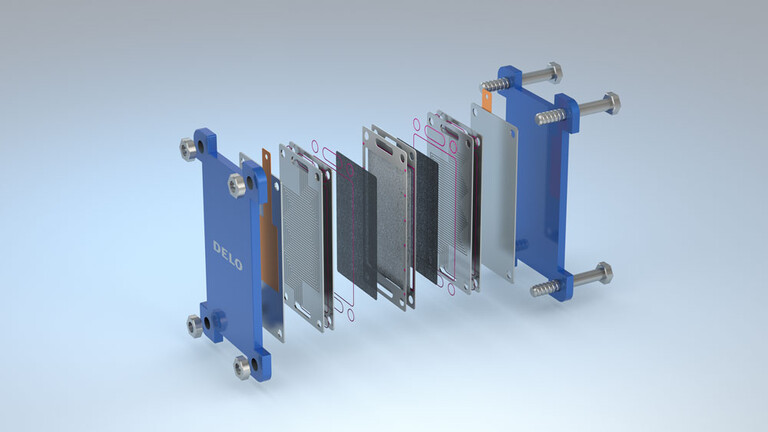

DELO is a leading manufacturer of industrial adhesives based in Windach near Munich. DELO adhesives can be used for various applications within a fuel cell stack. For example, they enable the bonding and sealing of the two half-shells that make up a bipolar plate. They also ensure that the media circuits (hydrogen, oxygen, coolant) of the stack are reliably sealed to each other and to the outside. Finally, the adhesives can also be used to fix components, such as the gas diffusion layer, within the stack assembly in order to ensure rapid further processing. The light-curing or pre-activatable adhesives and sealants are optimised for fast, precise and fully automated production.

It's evident that we are just at the beginning of an exciting journey. Our initial results are promising and show that the application of adhesives using digital printing makes it possible to make a significant contribution to the more efficient manufacture of fuel cells.

With further research and development, this area will undoubtedly continue to grow and change the way we use and apply adhesives.

©DELO

Exploded view of fuel cell, adhesive areas magenta-coloured

#Insights

Successes and visions

In conversation with the duo Daniel Scheer (Sales) & Stefan Holzer (Technology)

Business Division Managers at THIEME Printing Systems

With innovative approaches and customised solutions, they want to ensure that our company shapes the market through continuous innovation.

The last 3 blog entries

Our printing technologies at trade fairs 2024

Mar 11, 2024

Read article

Combined expertise in a dynamic duo

Aug 16, 2023

Read article

Why our digital printing machines are unbeatable in industrial digital printing!

Jun 30, 2023

Read article